- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-31 Origin: Site

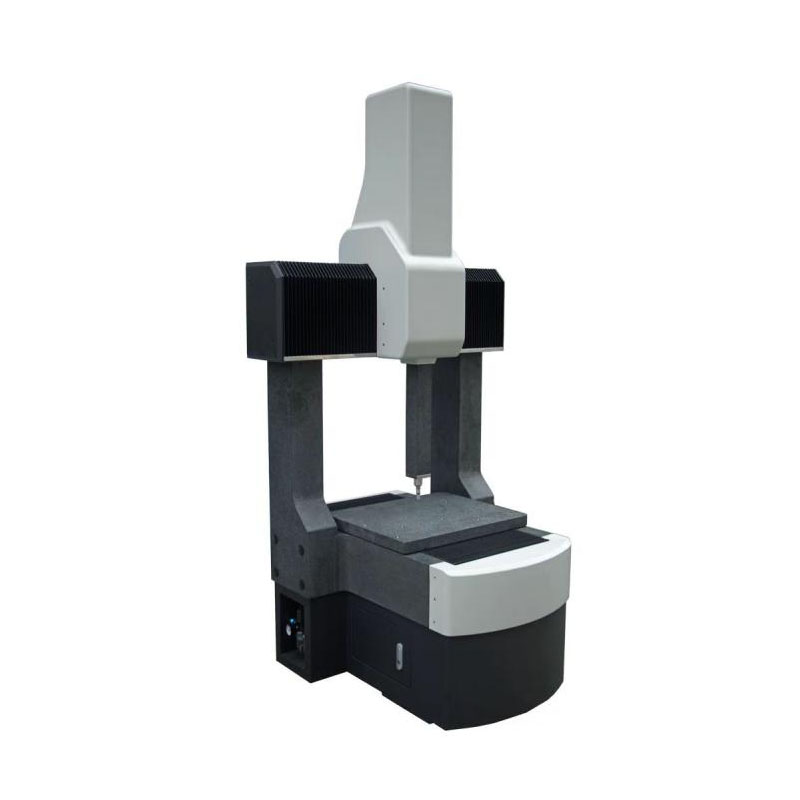

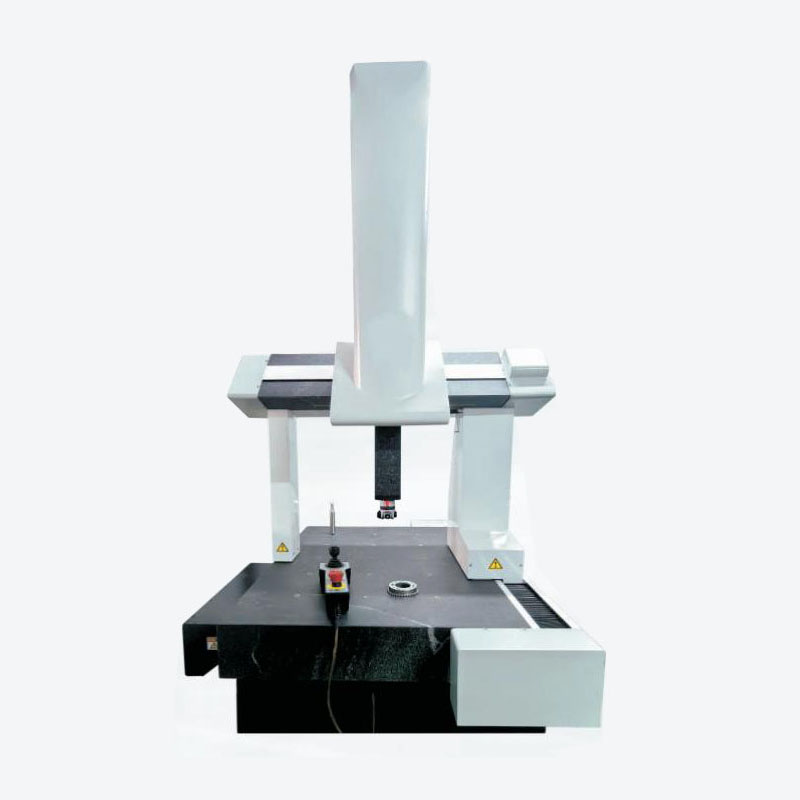

What’s the secret to achieving flawless precision in manufacturing? The answer is Coordinate Measuring Machines (CMMs). These vital tools ensure accuracy across industries like automotive and aerospace. In this article, we’ll examine how CMMs work, the factors influencing their accuracy, and how companies can maximize their use for improved manufacturing results.

Accuracy in manufacturing refers to how closely a part's measurements align with its intended specifications. This is critical for ensuring that components fit together correctly, function as intended, and meet performance and safety standards. Manufacturing tolerances, which define the allowable deviations from the target measurements, are critical to every industry. CMMs are designed to measure within these tight tolerances, ensuring parts meet the required specifications.

CMMs have become central to modern measurement systems. CMMs provide consistent, precise, and automated measurement, reducing the risk of human error that often accompanies manual measurement techniques. With the ability to measure complex geometries and even microscopic dimensions, CMMs are essential for ensuring the accuracy of parts across industries where precision is critical, such as in automotive or aerospace manufacturing.

Accuracy in the context of CMMs refers to how close the machine’s measured values are to the true values of the part being inspected. This involves both repeatability and resolution. Repeatability ensures the machine can measure the same part multiple times with consistent results, while resolution refers to the smallest change in measurement that the CMM can detect.

Term | Definition |

Accuracy | The closeness of the measured value to the true value. |

Repeatability | Consistency in measurement under the same conditions. |

Resolution | The smallest detectable change in measurement. |

While CMMs are highly precise, several factors can affect their accuracy. These include the type of probe used, the environmental conditions where the machine is located, and the regular maintenance and calibration of the machine. Even minor changes in these variables can lead to deviations in measurements.

The type of probe used in CMMs plays a significant role in measurement accuracy. CMMs use different types of probes, such as mechanical, optical, or laser probes. Laser probes, for example, offer high accuracy for non-contact measurements, while mechanical probes are typically used for tactile measurements.

Probe Type | Accuracy | Best Use Case |

Mechanical | High for tactile measurements | Suitable for contact-based measurements, like dimensional checks. |

Optical | Very high for surface measurements | Ideal for non-contact measurements of delicate or intricate parts. |

Laser | Extremely high in certain applications | Best for 3D scanning of complex geometries without contact. |

Environmental conditions, such as temperature, humidity, and vibration, play a critical role in the accuracy of CMM measurements. Even slight changes in these factors can lead to measurement errors, impacting the overall quality of the results. For instance, temperature fluctuations can cause the components of the CMM to expand or contract, leading to inaccurate readings. Similarly, high humidity can result in condensation on sensitive parts, while vibrations in the surrounding environment can cause fluctuations in measurements.

To mitigate these issues, maintaining a controlled environment is essential. Temperature control ensures that the machine operates within a consistent range, preventing parts from expanding or contracting. Humidity control is also crucial, as it prevents condensation from forming on the machine's sensitive components, which could interfere with measurement accuracy. Lastly, vibration-dampening tables or enclosures help minimize the impact of vibrations, stabilizing the measurements and improving overall precision.

Regular calibration and maintenance are critical for maintaining CMM accuracy. Calibration ensures that the machine's readings are consistent with standardized measurement systems, while routine maintenance helps prevent mechanical issues that could compromise precision.

Calibration Interval | Impact on Accuracy | Recommended For |

Daily | Keeps precision stable | High-precision industries |

Monthly | Ensures minimal drift | Standard manufacturing setups |

Annually | Prevents significant errors | Low to medium tolerance environments |

CMMs are designed to measure parts within specific tolerances—limits that define the acceptable range of variation in a part’s dimensions. The accuracy of a CMM is often expressed as a percentage of the total tolerance, which helps determine how reliably the machine can measure within those limits.

Tolerance Range (µm) | CMM Accuracy | Use Case |

0.5 - 1 µm | Very High | Aerospace, automotive precision parts |

1 - 5 µm | High | Medical device components |

> 5 µm | Moderate | General manufacturing |

While CMMs offer exceptional accuracy, it's important to compare them to traditional measurement tools like micrometers and calipers. Micrometers are highly accurate for small dimensions but are limited to simple parts. CMMs, on the other hand, can measure complex 3D geometries and offer higher consistency in measurements.

Measurement Method | Accuracy | Advantages | Limitations |

CMM | Very High | Ideal for complex parts, high repeatability | Requires calibration, high cost |

Micrometer | High for small parts | Very precise for small dimensions | Limited to small, simple parts |

Calipers | Moderate | Affordable, easy to use | Prone to human error, less precision |

To maximize the accuracy of CMMs, businesses need to follow best practices in calibration, maintenance, and operator training.

To maintain accurate measurements, CMMs should be calibrated regularly, especially if used in high-precision environments. Routine cleaning and mechanical checks also ensure that the machine functions optimally.

Maintenance Action | Frequency | Importance |

Cleaning probes | Weekly | Prevent debris buildup that affects measurements |

Checking mechanical parts | Bi-weekly | Ensure parts are working without wear and tear |

Recalibration | Monthly or after 100 measurements | Keeps measurement accuracy at optimal levels |

Skilled operators are crucial for obtaining accurate measurements from a Coordinate Measuring Machine (CMM). Proper training ensures that operators are familiar with machine settings, how to adjust them, and how to interpret the data accurately. Without adequate training, even the most advanced CMMs can yield inaccurate results.

Training for CMM operators typically falls into three categories. Basic operation training is provided during the initial onboarding and through refresher courses. This focuses on machine settings and basic operation procedures. Advanced calibration training is typically conducted bi-annually to ensure that operators can maintain precision in more complex measurements. Additionally, error troubleshooting training is provided as needed, focusing on how to address issues caused by environmental factors or machine malfunctions. This ongoing training ensures that operators can handle various challenges and maintain the accuracy of CMM measurements.

The automotive industry requires extremely precise measurements for everything from engine parts to chassis. CMMs are used to inspect parts during manufacturing, ensuring they meet strict quality standards.

In automotive manufacturing, engine parts such as pistons and valves must be measured with extreme precision. CMMs help ensure that these parts meet exact specifications for optimal performance.

CMMs reduce rework and scrap in automotive production by ensuring that parts meet specifications the first time. This increases throughput and minimizes waste.

The aerospace industry relies on CMMs for high-precision measurements due to the critical nature of its components. Even minor inaccuracies can lead to catastrophic failures.

Aircraft components like turbine blades and wing parts must be measured with sub-micron accuracy. CMMs are crucial in ensuring these parts meet stringent tolerances.

CMMs allow aerospace manufacturers to achieve tolerances that would be impossible with traditional measurement methods, ensuring the safety and reliability of each component.

High CMM accuracy ensures that parts are made right the first time, reducing defects and the need for costly rework.

CMMs simplify quality control by providing consistent and reliable data that can be used to identify defects early in the production process.

With accurate CMM measurements, manufacturers can minimize material wastage, ensuring that each part is within its specified dimensions.

By ensuring that parts are correctly measured and fit together properly, CMMs help reduce production delays caused by defective components.

CMMs are crucial for achieving accuracy and precision in modern manufacturing. By understanding the factors influencing CMM accuracy and properly maintaining these machines, businesses can optimize their production processes, reduce waste, and enhance product quality. Forth manufactures advanced Coordinate Measuring Machines that play a key role in delivering exceptional results, especially in high-precision fields such as automotive and aerospace. For industries that demand the highest standards, CMMs from Forth are indispensable tools for success.

Q: How accurate is a Coordinate Measuring Machine (CMM) measurement?

A: A Coordinate Measuring Machine (CMM) can measure with extremely high accuracy, often within a few microns. The precision depends on the machine's quality, probe technology, calibration, and environmental conditions.

Q: What factors affect the accuracy of a CMM?

A: The accuracy of a CMM is influenced by factors such as probe type (mechanical, optical, laser), calibration, temperature, humidity, and vibration in the environment.

Q: Why is calibration important for CMM accuracy?

A: Calibration ensures that the CMM measures accurately by adjusting the machine's readings to match known standards. It helps maintain consistent precision over time.

Q: How does a CMM compare to traditional measurement methods?

A: CMMs are far more accurate than traditional methods like calipers or micrometers, especially for complex or 3D measurements. They offer repeatability and reduce human error.