- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-07 Origin: Site

Coordinate Measuring Machines (CMMs) are essential in industries that require precision and quality control. Understanding their lifespan is crucial to maintaining high standards and avoiding unnecessary costs. This article explores the factors that affect CMM longevity, how long they typically last, and best practices for extending their life.

The longevity of CMMs directly impacts their efficiency and accuracy in production. These machines play a key role in ensuring high-quality standards across industries like aerospace, automotive, and medical devices. With proper care, CMMs can serve businesses for years, providing reliable performance and consistent measurements.

In sectors where even the smallest error can result in defective products or safety issues, the durability of CMMs becomes a matter of significant importance. The ability to maintain accurate measurements over time is essential for producing parts that meet high-quality standards.

Several factors contribute to the lifespan of a CMM, including usage intensity, maintenance, environmental conditions, and technological advancements. Proper management of these factors can significantly extend the life of your CMM.

Factor | Impact on CMM Lifespan | Best Practices |

Usage Frequency | Increased use leads to more wear and tear | Regular checks on usage intensity |

Maintenance | Poor maintenance leads to inaccuracies and failures | Routine calibration and cleaning |

Environment | Harsh environments (extreme temperature, humidity) | Keep CMM in a controlled environment |

Technology | Outdated models may need upgrades or replacements | Keep CMM updated with new technology |

CMMs ensure that parts are produced with high precision, which is critical in industries like aerospace, automotive, and medical devices. Accurate measurements guarantee product quality and help prevent errors that could lead to costly rework.

Industry | Role of CMM | Impact of Accurate Measurements |

Aerospace | Measures complex geometries | Ensures safety and compliance with regulations |

Automotive | Verifies parts’ dimensions | Improves efficiency, reduces waste and defects |

Medical | Inspects medical device components | Guarantees functionality and safety |

An aging or poorly maintained CMM can cause unplanned downtime, affecting production schedules and product quality. Minimizing downtime through regular maintenance is essential to ensure manufacturing efficiency.

Understanding the primary factors that influence CMM lifespan is essential for maximizing the machine’s performance and avoiding premature failure. These factors include usage frequency, environmental conditions, and the quality of maintenance.

Frequent use of a CMM (Coordinate Measuring Machine) accelerates wear and tear, shortening its lifespan. For machines with high usage, more frequent maintenance and upgrades are necessary to prevent degradation. In contrast, low-frequency use results in slower wear, but regular maintenance is still required. By managing usage and scheduling proper maintenance, businesses can extend the life of their CMM.

Routine calibration and proper maintenance are the most effective ways to extend a CMM’s life. Proper upkeep ensures that the machine operates accurately and efficiently throughout its service life.

Maintenance Action | Frequency | Importance |

Regular Calibration | Monthly or quarterly | Maintains measurement accuracy and consistency |

Routine Cleaning | Weekly | Prevents debris buildup and reduces wear and tear |

Mechanical Inspections | Bi-annual | Ensures components function as intended |

Environmental factors such as temperature, humidity, and dust can have a significant impact on the lifespan of CMMs. Keeping the machine in an optimal environment is crucial for maintaining its performance and durability.

Environmental Factor | Impact on CMM Performance | Solutions |

Temperature | Can cause expansion or contraction | Use temperature-controlled environments |

Humidity | Can cause condensation and corrosion | Keep CMMs in dry, humidity-controlled areas |

Dust and Debris | Can interfere with probes and components | Regular cleaning and use of protective covers |

As technology advances, older CMM models may become outdated or less efficient. Newer models with improved sensors and software can enhance the performance and extend the lifespan of a CMM.

New Technology | Impact on CMM Durability | Example of Improvement |

Advanced Probes | Improve accuracy and flexibility | Faster, more precise measurements |

Software Upgrades | Improve data processing and control | Enhanced capabilities for complex geometries |

Upgrading key components such as probes, sensors, or software can significantly improve the performance of older CMMs (Coordinate Measuring Machines), allowing them to maintain accuracy and functionality without the need for a full replacement. Upgrading probes and sensors enhances accuracy and precision, which in turn extends the machine's functionality and ensures more reliable measurements. Similarly, software upgrades increase operational efficiency and expand the CMM’s capabilities, improving both its performance and longevity. These upgrades help businesses maximize the value of their existing equipment while extending its service life.

The typical lifespan of a CMM is between 10 and 20 years, but this depends on factors like usage frequency, maintenance practices, and the environmental conditions it operates under.

On average, CMMs can last 10 to 20 years. However, the actual lifespan will vary depending on how the machine is used and maintained.

CMM Model | Typical Lifespan (Years) | Usage Type |

High-end models | 15-20 | Heavy industrial use |

Standard models | 10-15 | Light to moderate use |

Many companies report their CMMs lasting beyond 15 years with proper maintenance. For example, a CMM in an automotive factory might exceed 18 years of reliable service.

Industry | CMM Model Age | Performance at End of Life |

Automotive | 18 years | Continued high precision and accuracy |

Aerospace | 15 years | Still accurate, but outdated technology |

Aging CMMs may show signs of decreased accuracy, such as inconsistent measurements and slower performance. These signs indicate that the machine may need attention or replacement.

When repair costs increase and replacement parts become scarce, it may be more cost-effective to replace the CMM rather than continue with repairs.

Indicator | Sign of Wear | Action Needed |

Inconsistent Accuracy | Machine starts giving inaccurate readings | Calibration or replacement needed |

High Repair Costs | Repair expenses exceed replacement cost | Consider upgrading or replacing |

Regular calibration and cleaning are essential for ensuring your CMM operates at peak performance and lasts as long as possible.

Maintenance Action | Frequency | Importance |

Regular Calibration | Monthly or quarterly | Maintains measurement accuracy and consistency |

Routine Cleaning | Weekly | Prevents debris buildup and reduces wear and tear |

Mechanical Inspections | Bi-annual | Ensures components function as intended |

Skilled operators play a crucial role in extending the lifespan of CMMs. Proper training can reduce machine strain and increase efficiency.

Create a routine maintenance schedule that includes tasks such as calibration, cleaning, and mechanical inspections to keep the CMM in optimal condition.

In some cases, professional servicing is necessary to ensure CMMs maintain high accuracy and functionality. Experts can perform more advanced repairs and diagnostics.

Identifying when to replace a CMM (Coordinate Measuring Machine) is crucial for maintaining productivity. Signs that your CMM may need replacement include frequent downtime, consistent inaccuracies, or an outdated system that no longer meets your needs. Upgrading to a newer model can provide enhanced features, faster measurements, and improved accuracy, ultimately boosting overall productivity. When deciding between repairing and replacing your CMM, it’s important to weigh the costs of repairs against the benefits of investing in a new machine. Consider the long-term impact on productivity, potential for future upgrades, and the overall performance improvements before making your decision.

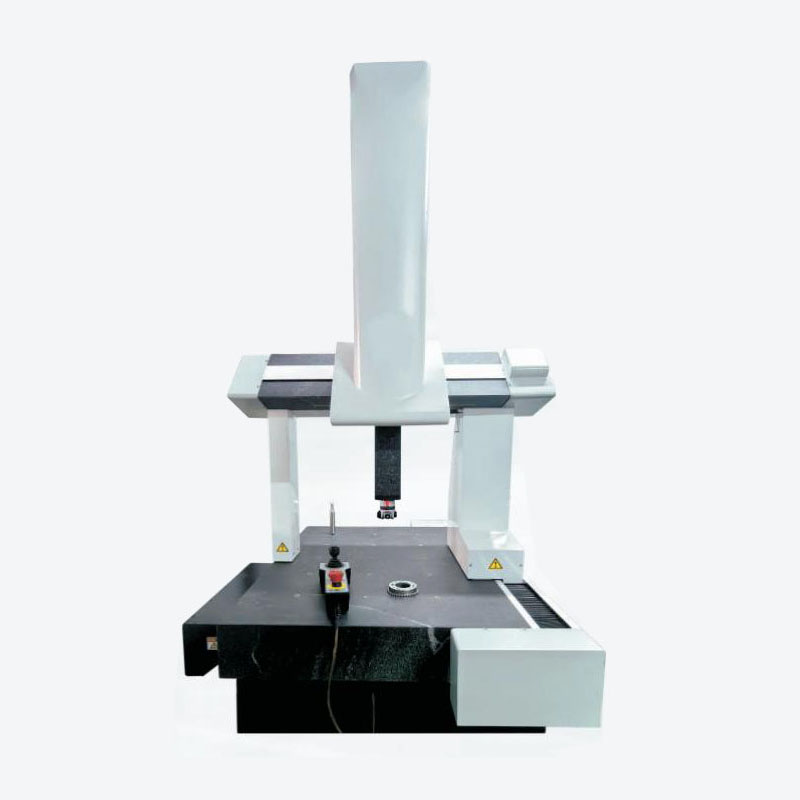

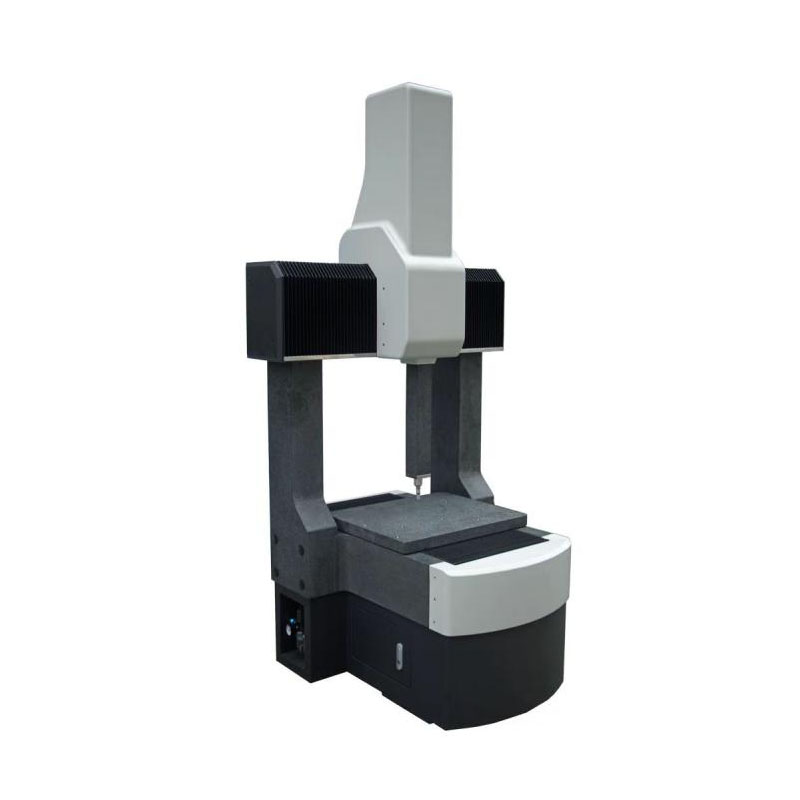

By following proper maintenance protocols, CMMs can provide long-term value, helping ensure high-quality production over many years. Investing in regular maintenance and staying current with CMM technology upgrades ensures that your equipment continues to deliver top-tier performance and reliability. At Forth, we specialize in manufacturing advanced Coordinate Measuring Machines (CMMs) that are designed to meet the highest standards of accuracy and durability. Invest in Forth's CMMs today to enhance your production efficiency and achieve consistent, precise results for years to come.

A: On average, a Coordinate Measuring Machine (CMM) lasts between 10 to 20 years, depending on factors like usage, maintenance, and environmental conditions.

A: The lifespan of a CMM is influenced by usage frequency, maintenance quality, environmental conditions, and the type of technology used in the machine.

A: Regular calibration, cleaning, and maintenance are key to extending the lifespan of your Coordinate Measuring Machine (CMM). Proper environmental conditions also help preserve its accuracy.

A: If your Coordinate Measuring Machine (CMM) shows signs of performance decline, increasing repair costs, or technological obsolescence, it may be time to replace it.

A: If your CMM starts providing inaccurate measurements, experiences slower operation, or shows signs of wear, it may require servicing or repair.