- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-12 Origin: Site

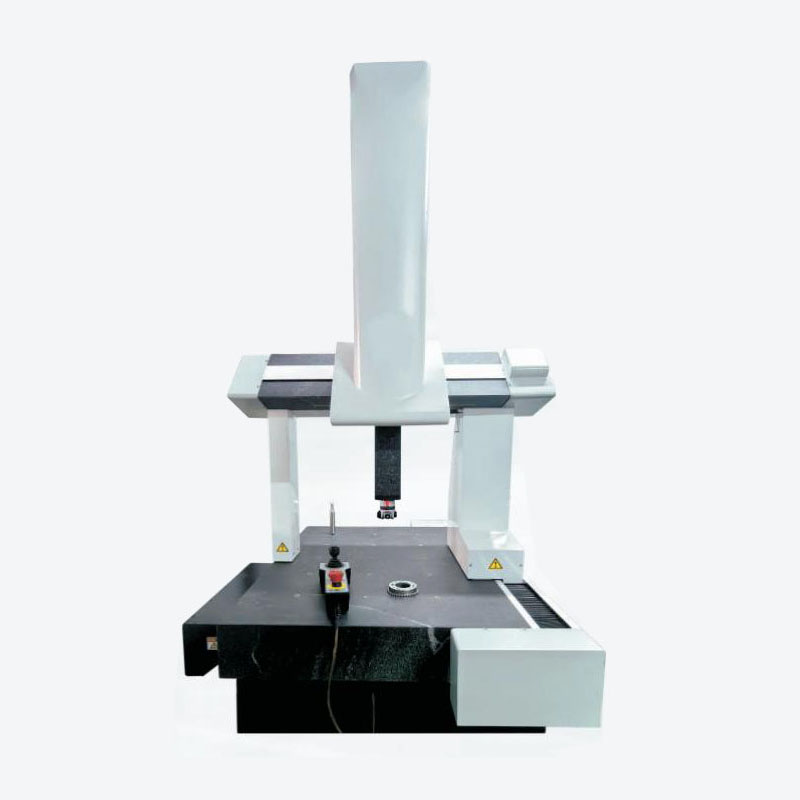

Have you ever wondered how precision manufacturing ensures parts fit perfectly? The answer lies in true position checks.A Coordinate Measuring Machine (CMM) is used to measure critical features, ensuring they meet design specifications. One of the most vital measurements it makes is the true position, which guarantees proper fitment during assembly.In this article, you will learn how to check true position on a CMM and why it's crucial for industries like aerospace and automotive.

In CMM, true position refers to the actual location of a feature or hole relative to its ideal or nominal location, typically described in the part's technical drawing using Geometric Dimensioning and Tolerancing (GD&T). Unlike simple measurements of linear distance or angles, true position accounts for the 3D relationship between features on a part.

True position is often specified as a tolerance zone, which defines how much the measured feature can deviate from the ideal position while still being acceptable. This tolerance zone is usually circular for holes and can be described by a diameter that indicates how far a feature can shift in any direction.

Feature Type | Tolerance Zone (Diameter) | Deviation Allowed | Example Application |

Hole | Ø0.05 mm | ±0.05 mm | Assembly fitment in automotive components |

Slot | Ø0.1 mm | ±0.1 mm | Precision alignment in aerospace parts |

True position ensures that parts will assemble correctly, even if they are mass-produced. Small deviations in position can result in poor fit, misalignment, or failure during use, especially in high-precision industries like aerospace and automotive manufacturing.

For example, in aerospace applications, even a slight misalignment in a hole can impact the integrity of an entire component, potentially causing operational failures. Similarly, in automotive manufacturing, precise hole placement is essential for components like engine parts or chassis assembly, where improper fit could affect performance or safety.

Before checking the true position, ensure that both the CMM machine and the part are properly prepared:

A CMM setup checklist is essential for ensuring accurate measurements and efficient operation. Start by cleaning the workpiece to remove dust, grease, and debris, which could interfere with measurements. Next, align the part by securing it properly on the CMM fixture or table to ensure it remains stable during measurement. Finally, calibrate the CMM to ensure the probe and machine are correctly set up for accurate readings. Following these steps ensures precise measurements and optimal performance of the CMM.

Selecting the correct CMM probe is critical for accurate true position measurement. Probes vary in size, shape, and technology, with options like mechanical, optical, and laser probes available. For true position measurements, choose a probe that offers high precision and stability.

Probe Type | Description | Best Use Case |

Mechanical | Contact-based, tactile probe | For measuring hard surfaces or metal parts |

Laser | Non-contact, uses laser beams | Ideal for delicate or soft materials |

Optical | Non-contact, uses light and cameras | Fast, precise measurements for high-speed applications |

Once the machine is set up and the right probe is selected, proceed with measuring the true position of the features:

The True Position Measurement Procedure involves several key steps to ensure accurate results. First, define the reference point, which is the starting point for measuring the true position of the feature. Next, measure the feature using the CMM probe to capture the position of the feature, such as the center of a hole. Finally, analyze the data by calculating the deviation from the nominal position using the CMM software, which helps determine if the feature’s position meets the required specifications. This process ensures precise alignment and positioning in manufacturing.

Misalignment of the part or the CMM probe is a common issue that can lead to inaccurate true position readings. Misalignment during setup or calibration can result in errors that affect the entire measurement process. To minimize misalignment:

Common Issue | Solution |

Misaligned Part | Secure the part firmly on the CMM fixture. |

Improper Calibration | Calibrate the machine regularly and before each measurement. |

True position measurements are often governed by tolerances, which specify the allowable deviation from the nominal position. Understanding how these tolerances work is crucial for accurate assessments.

Tolerance Type | Impact on Measurement Accuracy | Example |

Loose Tolerances | Higher deviation allowed, more leniency | Manufacturing of less critical components like brackets |

Tight Tolerances | Smaller deviation allowed, stricter fit | Aerospace and automotive parts where precision is critical |

In some cases, probe access may be limited due to the geometry of the part. Difficult-to-reach features can be challenging to measure accurately, and any probe interference can lead to errors.

Probe access challenges can arise in various situations during CMM (Coordinate Measuring Machine) operations. When there is limited space for the probe, using articulating probes or extendable arms can provide greater flexibility and reach to access tight areas. For obstructed features, positioning the probe at different angles allows the operator to effectively access and measure the feature, ensuring accurate results even in challenging setups. These solutions help overcome common access issues, improving the efficiency of the measurement process.

Many modern CMMs come equipped with powerful software solutions that can improve the accuracy and repeatability of true position measurements. These software tools help:

Software Feature | Benefit |

Automated Data Processing | Reduces human error and speeds up analysis. |

Real-Time Feedback | Helps adjust measurements during the process. |

Advanced Filtering Options | Enhances precision by filtering out noise. |

Probe stability is crucial for ensuring accurate true position measurements. Variations in probe pressure or instability can introduce errors. To improve stability:

Enhancing probe stability is critical for ensuring accurate measurements. One effective technique is to use rigid probes, which help prevent bending or deflection during measurements, ensuring that the probe maintains its position and provides reliable data. Another technique is to use low-contact force probes, which minimize the impact on soft or delicate surfaces, preventing damage while still obtaining precise measurements. These methods enhance probe stability, resulting in more accurate and consistent results.

In aerospace and automotive industries, true position measurements are critical for ensuring that complex components fit together correctly. For example, in aerospace, misalignment of holes in an aircraft wing could lead to catastrophic consequences. CMMs help ensure that every hole, pin, or fastener aligns perfectly with the assembly requirements.

Industry | Application | CMM Role |

Aerospace | Aircraft wing assembly | Ensures that all components align perfectly to prevent structural failure. |

Automotive | Engine assembly and chassis alignment | Verifies that holes and fittings are in the exact location for optimal performance. |

In electronics manufacturing, true position measurements help ensure the precise placement of components on circuit boards or other assemblies. Accurate true position checks ensure that components like capacitors, resistors, and chips align correctly, preventing failures in the final product.

True position checks on Coordinate Measuring Machines (CMMs) are essential for ensuring precision and quality in manufacturing. By correctly measuring the true position of features, manufacturers can guarantee proper assembly and functionality of parts. Best practices include preparing the workpiece and CMM setup thoroughly, selecting the appropriate probe, and overcoming common challenges like misalignment and access issues. Additionally, software and advanced probes can help improve measurement accuracy. Industries like aerospace, automotive, and electronics rely heavily on true position checks to maintain the integrity of their products. Investing in high-quality CMM equipment and proper training ensures that manufacturers can produce parts that meet the strictest standards. By focusing on true position checks, you can enhance your production processes and ensure long-term reliability in your products. This is where Forth comes in—providing cutting-edge CMM equipment and training to help manufacturers maintain the highest standards of precision and quality.

A: True position refers to the exact location of a feature on a part relative to its ideal position, typically specified using Geometric Dimensioning and Tolerancing (GD&T) on a CMM. It ensures that parts fit correctly during assembly, meeting design specifications.

A: To check true position on a CMM, first secure and calibrate the part. Use a probe to measure the feature's position and compare it with the nominal position. The CMM software will calculate the deviation and determine if it falls within the specified tolerance zone.

A: Checking true position ensures that parts meet tight tolerances, ensuring proper fitment and functionality. This is crucial for industries like aerospace and automotive, where misalignment can result in assembly failure or performance issues.

A: A Coordinate Measuring Machine (CMM) equipped with appropriate probes (mechanical, optical, or laser) is needed to check true position. Software that processes the probe data and compares it with the ideal position is also essential for accurate measurements.